Description

Features

- Heat cure acrylic denture base material

- Simple mixing, easy to process

- Variety of shades (Pink, Light Pink, Veined, Clear)

- Cross linking ensures superior quality.

Description

Heat Cure acrylic denture base material. Simple mixing, easy to process. Cross linking ensures superior quality.It is widely used in the fabrication of dentures and other dental prosthetics. It is designed to provide durability, strength, and aesthetic appeal while ensuring a comfortable fit. Heat curing is an essential process in the application of this material, involving polymerization under controlled heat and pressure, which helps achieve high density and smoothness in the final product. The material is resistant to discoloration and staining, offering long-lasting results. Known for its biocompatibility, DPI Heat Cure minimizes the risk of allergic reactions or irritation in patients, making it a popular choice in restorative dentistry for creating reliable, lifelike, and comfortable dental appliances.

INDICATIONS:

- Removable complete denture

- Removable partial denture

- Orthodontic appliances

- Oral & Maxillofacial prosthesis

- Obturators

- Relining & Rebasing of dentures

Key Specifications

Variety of shades (Pink, Light Pink, Veined, Clear)

- Flexural Strength: High flexural strength

- Biocompatible

Packaging

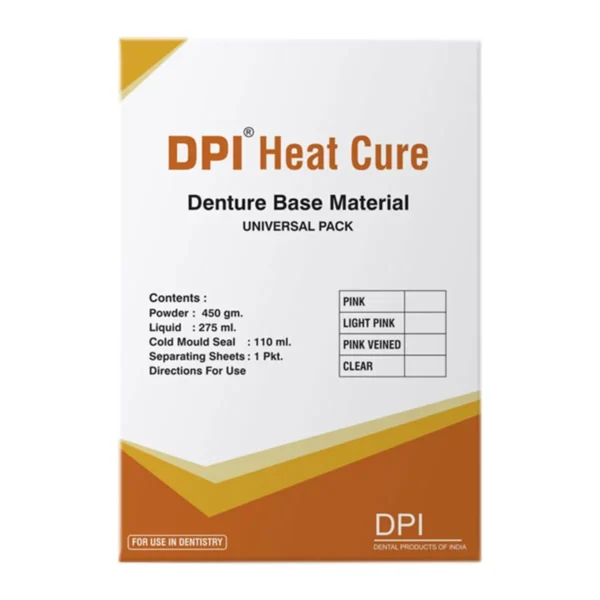

Dpi Heat Cure Universal Pack – (Clear, Veined & Pink)

- Powder: 450 gm.

- Liquid: 275 ml.

- Cold mold seal:110 ml.

- 3 Kg Jar.

Dpi Heat Cure Powder – (Clear, Veined & Pink)

- Powder 450 Gms.

Dpi Heat Cure Liquid

- Liquid 275 ml.

Dpi Heat Cure Liquid Tin

- 4 Ltr Tin.

Direction to Use

- Prepare the Model: Begin by preparing the dental model or mold, ensuring it’s clean and ready for acrylic application.

- Mixing: Combine the powder and liquid components of DPI Heat Cure in the recommended ratio. Mix until a uniform, workable paste is achieved.

- Packing: Once the mixture reaches the doughy stage, carefully pack it into the mold, pressing to avoid air bubbles or gaps.

- Curing Process: Place the packed mold in a curing unit or water bath to achieve optimal hardness.

- Cooling: Allow the mold to cool gradually to prevent stress fractures.

- Finishing and Polishing: Once cured, carefully remove, trim, and polish the acrylic to a smooth finish.

- Cleaning: Disinfect before use and check for any sharp edges or imperfections.

Additional Info

- Country of Origin: India

- Manufacturer: Dental Products of India

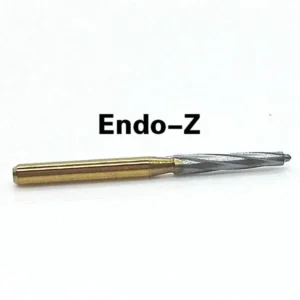

NMD Endo Endo-Z Tungsten Carbide Burs Access cavity enlarging bur with non-cutting tip

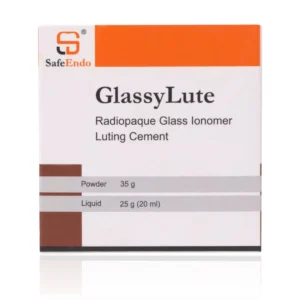

NMD Endo Endo-Z Tungsten Carbide Burs Access cavity enlarging bur with non-cutting tip  SafeEndo GlassyLute Restorative Luting Glass Ionomer Cement (GIC)

SafeEndo GlassyLute Restorative Luting Glass Ionomer Cement (GIC)

Reviews

There are no reviews yet.